Properties

Packing

Post by Mohsen Alamdar, Sep 05, 2019.

none-metallic

2000M—Super-high Temperature & Pressure Valve Packing

Braided from low-sulphur expanded graphite yarns with corrosion inhibitor,

reinforced with Inconel wire. Each yarn is round braided with Inconel mesh

again. The exclusive packing is formable, yet tough. Rated in steam service

500bar, maintains integrity in steam up to 650°C. It is a cost-effective as well

as a confident choice.

2000S

It is 2000I Inconel reinforced graphite packing with stainless steel

spring core, special for oval stem under high temperature.

2021I—High-temp Jacketed Valve Packing

High temperature fiber with inconel wire braided over a resilient graphite

core thoroughly impregnated with graphite and corrosion inhibitor, normal

for steam valve.

Farafan 2000P Graphite packing with PTFE impregnation

Made of expanded flexible graphite , which are reinforced by textile fibers,

with PTFE impregnation. Compared to traditional graphite packing , it has

excellent cross-section tightness, structural strength and very low

friction-value, wear resistant, yet gentle to shaft and stem.

Farafan 2010 Graphite packing with carbon fiber corners

Diagonally braided from expanded flexible graphite,reinforced at the

corners throughout with high quality carbon fiber. This corners and body

make it three times more resistant to extrusion and also increase the

pressure handing capabilities compared to 2000.

Farafan 2030 Graphite packing with PTFE corners

PTFE corners effectively prevent graphite extrusion, this packing contains the advantage of PTFE

and graphite. Graphited PTFE corner is also efficient.

APPLICATION:

Can be used in many demanding applications, both dynamic and static. Particularly suited for high

temperature and high pressure service in valves, pumps, expansion joints, mixers and agitators of

pulp and paper, power station and chemical plant etc.

2100 Carbonized Fiber Packing

Braided from shrink-proof synthetic fiber impregnated with PTFE

dispersion containing graphite particles, silicon-oil-free, which is oxidized

polyacrylonitrile fiber. Compared to traditional carbon fiber packing, it is

not brittle, can suited for high peripheral speeds and food industries.

Oxidized fiber has high strength and good thermal conductivity, PTFE

and graphite makes the packing have excellent self-lubrication, so this

packing does not damage shafts and has long life.

2100I Carbonized Fiber Packing Reinforced with Nickel wire

The wire reinforcement provides increased mechanical strength, usually for static.

APPLICATION

It can be used in weak acids and alkalis or media containing few grains of solid particles, both

dynamic and static, mainly used for centrifugal pumps, plunger pumps, mixers and valves.

Without cooling it can be used with hot water up to 160°C , with cooling it can be used with hot

water up to 207°C. Particularly ideal for hot water, condensate and main coolant pump

Farafan 2200 Aramid Fiber Packing

Braided from high quality aramide fibres with PTFE-Impregnation and

lubricant additive. Extremely hard wearing. It shows good chemical

resistance, high elasticity and very low cold flow. It is wear resistant but

may damage the shaft if not used properly. A minimum shaft hardness of

60HRC is therefore recommended. Compared with other kinds of packing, it

can resist more severe media and higher pressure. The packing is also

lubricated with a silicone-based compound for quick and easy break-in.

Spun Aramid fiber packing 2200S is also available on request.

Farafan 2200L Aramid fiber packing with an inert lubricant

An extremely durable, highly abrasive resistant packing, It is ideal for slurry service application.

APPLICATION

It is a universal packing which can be used for pumps in all types of industry such as chemical,

petrochemical, pharmaceutical, food and sugar industries, pulp and paper mills, power stations etc. It

is also a durable packing able to withstand granular and abrasive applications, it is recommended for

serve in superheated steam, solvents, liquefied gases, sugar syrups and other abrasive fluids.

For hot water applications it can be used uncooled up to 160°C.

It can be used as stand-alone packing also combined with others as anti-extrusion ring.

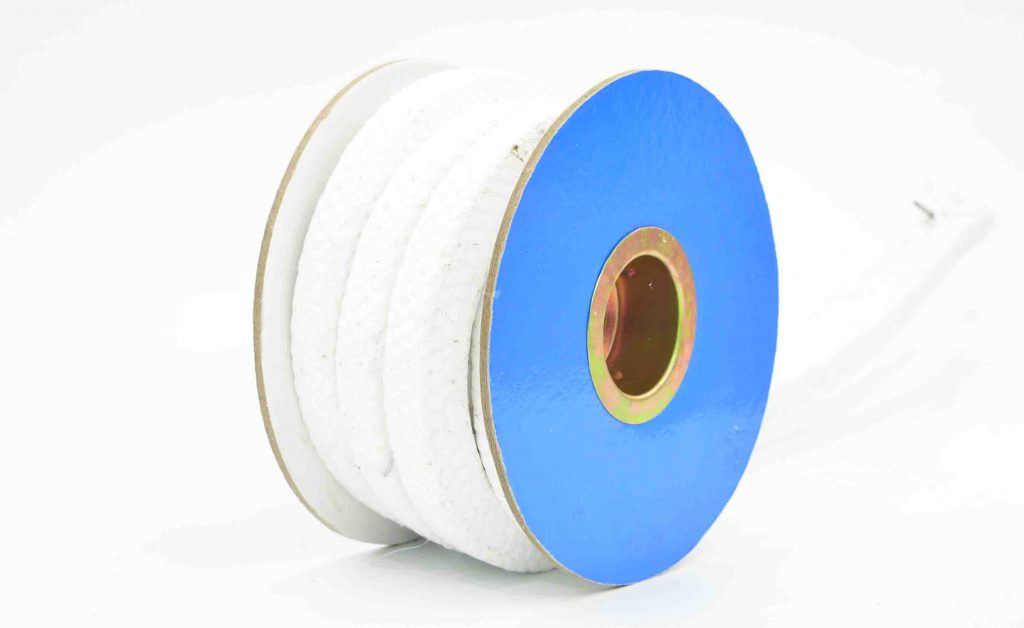

2220 White PTFE Packing with Aramid Corners

Multi-yarn packing, the corners of packing are made of aramid yarns

impregnated with PTFE, while the friction faces are made of pure PTFE

yarns. This structure enhances the lubrication ability of aramid fiber and

improves the strength of the pure PTFE.

2222 White PTFE & Aramid in Zebra Braided Packing

Multi-yarn in zebra braided packing consisting of pure PTFE and araimid.

2230 Graphited PTFE Packing with Aramid Corners

Interlock braid of graphited PTFE with aramid yarn on the corners. This improve resistance in

higher pressure applications. It has excellent sliding velocity and thermal conductivity compared to

2220

2232 Graphited PTFE & Aramid in Zebra Braided Packing

Compared to 2222, it has excellent lubrication ability and thermal conductibity.

2300(A/B) Pure PTFE Packing (Free oil)

Made of raw film twists of pure PTFE dispersion resins without any lubrication. It is soft,

mainly for static sealing. (2300P=2300 + PTFE Impregnation)

2300L Pure PTFE Packing with oil

Same as 2300, but treated with special lubrication, designed for dynamic.

PA 2300 and PA 2300L both are economical packing.

2302 Pure EPTFE Packing (Free oil)

Braided from pure 100% expanded PTFE packing. it is very flexible, low cold flow, high

elasticity. It can be impregnated with PTFE on request.

2304 Sintered PTFE Packing

Made of sintered, highly stretched PTFE multifilament yarns with thoroughly PTFE

impregnation. The packing is then re-impregnated with a mix of PTFE mix during plaiting

operation. Good resistance to compression and to extrusion, high structural and

cross-sectional density.

2320A/B Graphited PTFE Packing

Braided from graphited PTFE (GPTFE) yarn. The packing is soft. There are no free

particles of graphite on surface and therefore no contamination can occur.

2320L Graphited PTFE Packing with oil (2320C)

Packing made of 100% GPTFE yarns, and re-impregnated with a silicone lubricant. It is

also economical GPTFE packing

2322 Sintered Graphited PTFE Packing

Braided from sintered PTFE pretreated with graphite impregnation. This yarns are 100% from Leizing. The

characteristics are similar to GFO, just has cross-sectional density, and some particles of graphite on surface.

APPLICATION

For use in pumps, valves, reciprocating and rotating shafts, mixers and agitators. Especially designed for services

involving surface speeds and temperature higher than those normally specified for pure PTFE packings. Can be

safely used in all chemical pump applications with the exception of molten alkali metals, fluoride, fuming nitric

acid and other strong oxidizing agents. It is also against water, steam, petroleum derivatives, vegetable oil and

solvents.

2000--Flexible Graphite Packing

Braided from low-sulphur expanded graphite yarns, which are reinforced

by cotton fiber. It has a very low friction, does not damage shafts or

stems. It shows good thermal and chemical resistance and high elasticity.

Other reinforcement materials are also available:

Glass fiber--------High strength, lower cost

Carbon fiber------Less weight loss

2000K --Flexible Packing with Corrosion Inhibitor

Corrosion inhibitor acts as a sacrificial anode to protect the valve stem and the stuffing box.

APPLICATION

2000 & 2000K is a multi-service packing capable of a wide variety of uses throughout a plant. It can

be used in valves, pumps, expansion joints, mixers and agitators in high-pressure, high-temperature

hostile environments of hydrocarbon processing, pulp and paper, power stations, refineries and

industries where effective sealing is vital.

Precaution: in oxidizing environment.

Recommendation:

Use preferably with Farafan 2102 high carbon fiber anti-extrusion packing rings.

2400 Ramie Fiber Packing with PTFE

Highest quality ramie fiber impregnated with light-colored, special PTFE

and inert lubricant during square plaiting operation. It can prevent product

contaminated. Low maintenance, easy-to –control, it is not harsh on shafts

and stems. Material Flax is also available on request.

2400SC Ramie packing with silicon Rubber Core

High elastic silicon core can absorb vibration, to control leakage.

2400G Ramie Packing with graphite & oil impregnation

Square braided construction, graphite coated and mineral oil lubricated throughout.

Farafan 2440 Cotton Fiber Packing with grease

Pre-impregnated, twisted cotton yarns, intensively re-impregnated during

braiding. Flexible and elastic, easy to handle. It’s an economical packing for

the limits of application stated。

2440W is white,2440Y is yellow

Farafan 2440G Cotton Packing with Graphite & oil

Pre-impregnated cotton yarns treated with graphite, then thoroughly

re-impregnated during braiding. The packing is resilient and flexible.

Farafan 2440P Cotton Packing with PTFE Impregnation

Made of long cotton fiber yarn impregnated with PTFE and additives. The packing has a low coefficient of friction

& is resilient and flexible.(PH:4~10)

PA 2500 Arcylic Fiber Packing with PTFE

Braided from high strength arcylic synthetic fiber pre-impregnated with

PTFE, and re-impregnated during square braiding. It has excellent properties

of sealing, lubricating and resistance to chemicals.

2500L is acrylic fiber packing with oil and few PTFE

2500SC is Arcrylic fiber packing with silicon core

PA 2500G Arcylic Fiber Packing Treated with Graphite

Braided of high strength Arcylic synthetic fiber, treated with graphite.

The packing is then re-impregnated during braiding consisting of graphite mixed with special

lubrications. Much of graphite filler increases the service temperature and the density of the packing.

Farafan 2540 Kynol Fiber Packing

Braided from high-performance Kynol (also named novoloid or phenolic)

fiber impregnated with special PTFE lubricant, it has very good mechanical

properties combining softness and strength. The packing has natural golden

sheen. Compared to ordinary aramid and PTFE, it has more benefits as

follows:

★ Thermal stability, low heat expansion;

★ High dimensional stability and superior pressure resistance even at

elevated temperature;

★ Good process-ability, easy to cut and fit;

★ Outstanding chemical resistance particularly in acidic media;

★ Excellent resistance to organic solvents, oil and fuels…

Farafan 2542 PTFE Packing with Kynol fiber corners

It contains the advantage both PTFE and Kynol

APPLICATION:

A high performance packing that is well suited to applications where graphite impregnation may not

be acceptable. Suitable for abrasive media, and where contamination is not permitted. It has multiple

uses in chemical plants and pulp and paper mills, and is regularly used in rotating and reciprocating

pumps, washer journals, liquor pumps, refiners and digesters.

Leave a Comment: